BYD: From Smart Factory to Test Track

Inside BYD Zhengzhou

- January 15, 2026

-

9,964

9,964

Today, BYD represents far more than one of the world’s fastest-growing electric vehicle brands. It stands for a new way of thinking in the automotive industry one that redefines manufacturing, technology, and real-world driving experience.

A visit to BYD Zhengzhou Factory, followed by hands-on driving at a world-class test facility in Zhengzhou, China, makes one thing clear: BYD does not see electric vehicles as mere products. Instead, the brand is actively building a comprehensive new-energy mobility ecosystem designed for the present and scaled for the future.

The Origins of BYD: Built on Battery Expertise

Long before becoming a global EV leader, BYD began its journey in the battery business. This foundation gave the company a deep understanding of what truly powers electric vehicles their core energy systems.

Rather than following the traditional automotive playbook, BYD chose a different path. The brand develops and controls every critical component in-house, from batteries and electric motors to electronic control systems and final vehicle assembly. Nowhere is this philosophy more evident than at BYD Zhengzhou Factory.

BYD Zhengzhou Factory: A City of Electric Mobility

Located in the Zhengzhou Airport Economy Zone, BYD Zhengzhou Factory spans an impressive 10.67 square kilometers. It is designed to be far more than a conventional car plant.

Within this vast complex, BYD integrates every major process required for new-energy vehicle production, including:

-

Body forming, structural welding, painting, and final assembly

-

Manufacturing of electric motors, power electronics, and drivetrains

-

Interior components, body structures, lighting systems, and seating

-

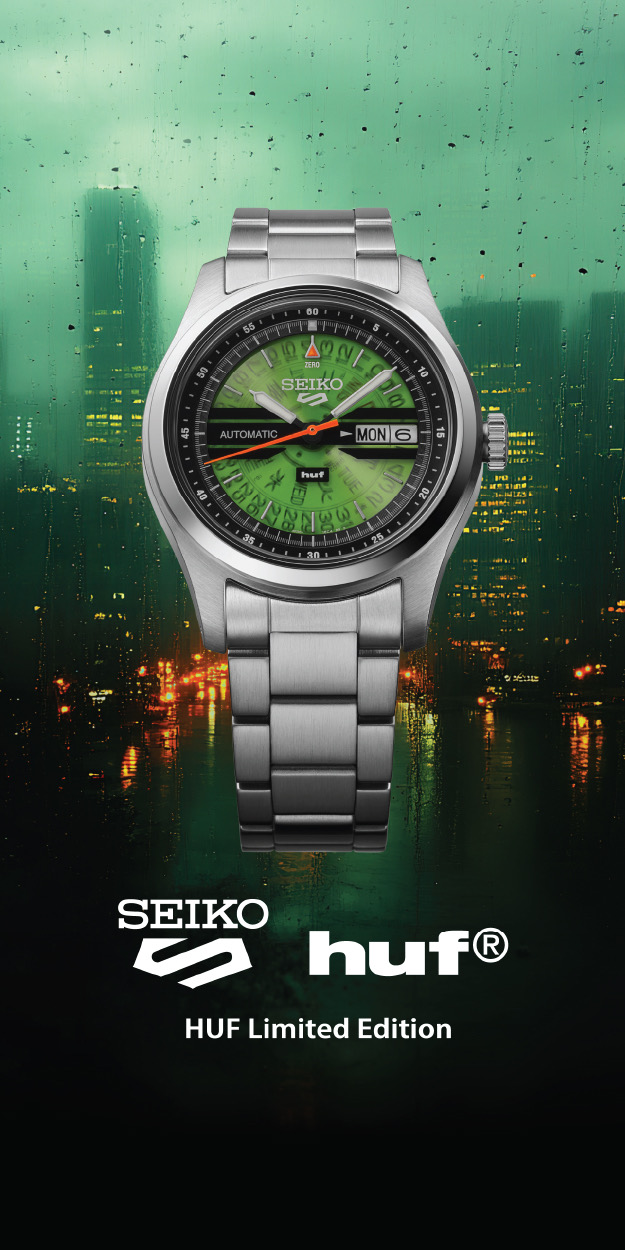

Production of Blade Battery and complete battery systems

-

Advanced materials manufacturing

BYD’s goal is clear: to establish a fully integrated industrial value chain within a single city allowing greater control over quality, lower production costs, and faster technological development.

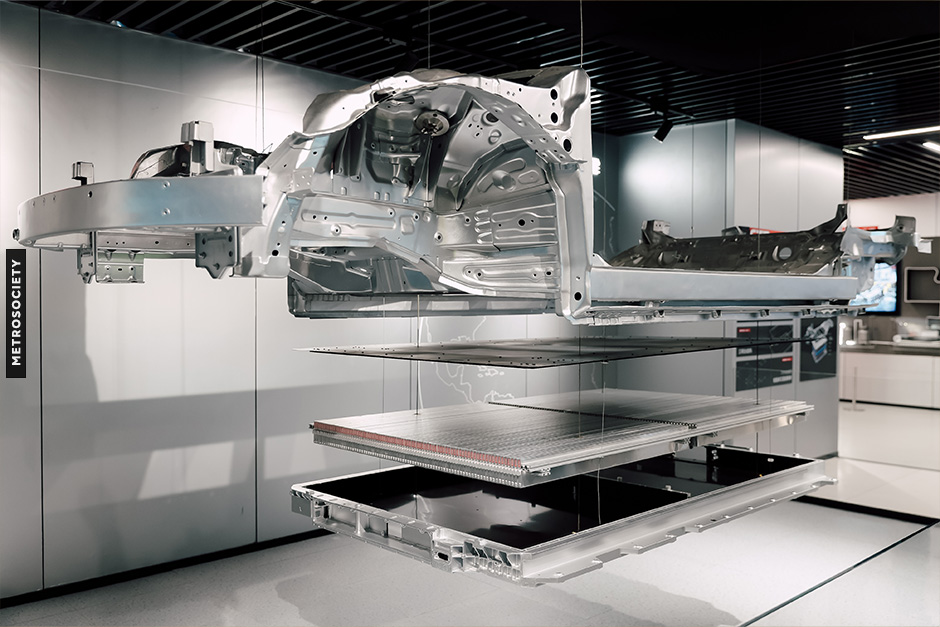

Smart Manufacturing: Precision as the Foundation

What truly sets BYD Zhengzhou Factory apart is its extensive use of advanced automation. In the structural welding process alone, industrial robots handle up to 98% of the work.

The production lines are capable of assembling multiple new-energy vehicle models using more than 11 advanced automated processes. Output reaches up to 50 vehicles per hour, while manufacturing tolerances are controlled to within 0.01 millimeters.

Every step of production is monitored in real time from raw materials to fully assembled battery packs. This level of precision and oversight is the unseen backbone behind BYD’s ability to compete on a global scale.

From Factory Floor to Test Track: BYD Zhengzhou International Circuit

Seeing how BYD builds its vehicles is only half the story. The full picture comes together on the track at BYD Zhengzhou International Circuit, a world-class testing facility dedicated to new-energy vehicles.

Designed to evaluate performance, safety, intelligent systems, and real-world usability, the circuit brings every aspect of vehicle development into one location. The main facility is divided into three levels:

-

Level 1: Vehicle testing zones, simulators, and performance demonstrations

-

Level 2: Brand and core technology exhibitions

-

Level 3: Hospitality and dining areas

One Track, Every Driving Scenario

The BYD test circuit features seven major zones, covering everything from high-speed driving to extreme off-road conditions:

-

Main Track: A 550-meter straight for speed and stability testing

-

Low-Friction Track: Simulated ice and snow surfaces for traction and stability control

-

Off-Road Area: Inclines up to 42 degrees with varied obstacles

-

Floating Water Pool: Demonstrating vehicle buoyancy capabilities

-

Sand Slope: A 29.6-meter-high simulated sand dune holding a Guinness World Record

Each zone exists to prove one thing: BYD’s technology is engineered to perform reliably in real-world conditions not just in controlled environments.

Yangwang U9: Redefining Electric Performance

One of the most striking experiences at the circuit was the Yangwang U9, BYD’s high-performance electric supercar under its premium sub-brand.

Key highlights include:

-

e⁴ (Yi Sifang) all-wheel drive system with four electric motors

-

Combined output of 1,306 horsepower

-

0–100 km/h in just 2.36 seconds

-

Cloud Chassis – X active suspension, reacting within 40 milliseconds

The U9 delivers more than raw speed. It offers confidence, composure, and intelligence demonstrating that BYD views electric vehicles as advanced technology platforms, not simply modes of transportation.

A Broader Vision of Electric Mobility

What stands out most from BYD’s presence in Zhengzhou is not a single car or innovation, but a cohesive vision. From smart factories and integrated supply chains to immersive test tracks and real-world driving experiences, BYD connects every element into one ecosystem.

This approach reflects a broader truth: the future of electric vehicles is not just about energy alternatives. It is about lifestyle, design, safety, and how technology seamlessly integrates into everyday life. And this is the direction in which the automotive world is clearly heading.